Market prospects of plant lighting in 2022

Next, we analyzed the development of the global plant lighting industry in 2021 from technical standards, corporate trends, application trends, etc., and provided valuable experience for lighting professionals involved in the plant lighting industry.

Plant lighting has been popular in Japan and Korea for a long time, and there is also a lot of attention in China. The sales market of LED plant lights is concentrated in countries and regions with fewer agricultural personnel such as Japan, South Korea, China, the United States, and Europe. However, with the increase in the penetration rate of LED plant growth lamps, the Chinese market has entered an explosive period. The survey shows that since 2013, the global output value of LED plant growth lamps has shown a rapid growth trend. Although the output value is only tens of millions of U.S. dollars, it is expected to exceed 35 million U.S. dollars in 2014 and challenge 300 million U.S. dollars in 2017.

In 2013, the cost of LED plant lights dropped significantly compared to 2010, equivalent to 0.38 NT per lumen, which was only one-fifth of the 1.8 NT in 2010, which drove the investment of major international manufacturers such as Philips, Osram, Mitsubishi, and Panasonic. . The innovative application of LED plant factories in Taiwan Province, which has the advantages of both LED and agricultural industry, certainly does not want to miss business opportunities. It adds scientific and technological innovation to agriculture and adds 100 million yuan to the enterprise. Taiwan Province has the advantages of developing special wavelength LED lights, product customization, low construction costs, overall solutions, and factory technology transfer. But it also faces problems such as insufficient government support, uneven products, and low brand awareness. At this stage, the first thing to be solved is the promotion strategy of LED plant lights.

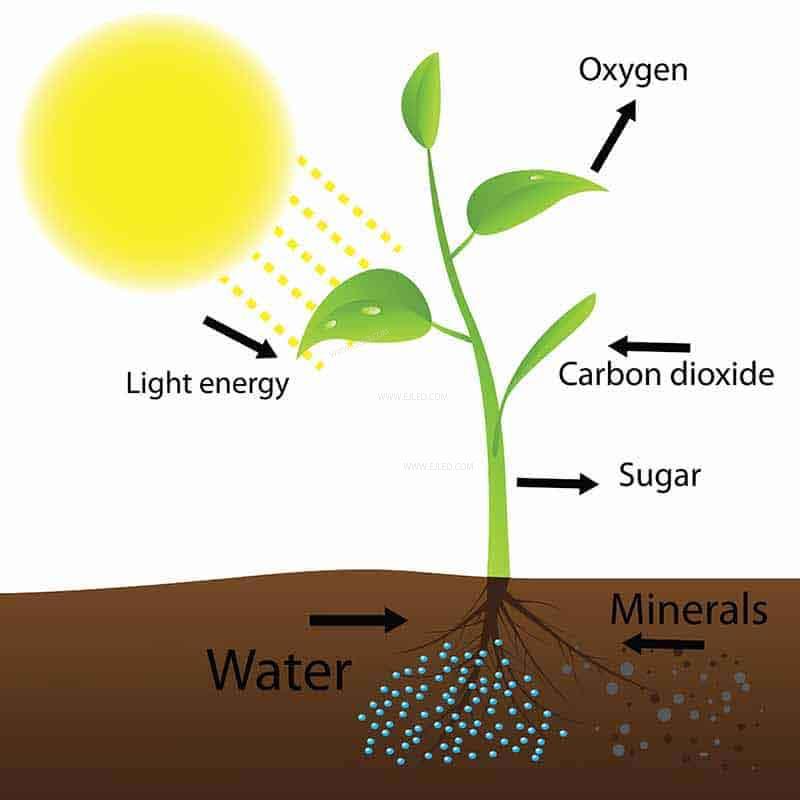

Plant factories originated in Denmark in 1957. Insufficient sunlight hindered the growth and development of plants. Later, Japan, the United States, and the Netherlands invested successively. However, due to factors such as high cost, insufficient technology, and insufficient experience, poor management has been caused. It wasn't until the 21st century that the greenhouse effect became more and more serious, which aroused the attention of all walks of life. From the perspective of agricultural development, the development of modern agriculture benefits from the use of fertilizers and pesticides, which can rapidly increase production, meet the huge food demand brought about by rapid population growth, and make a great contribution to solving global food and poverty problems. However, traditional agriculture is totally dependent on the weather. Growing crops is not only restricted by climate and seasons, but also cannot be produced as planned. Even if the crops are harvested, they will be affected by the decline in quantity and prices. In addition, in order to ensure the harvest, farmers use large amounts of pesticides to control pests and diseases. In order to increase production capacity, the excessive use of chemical fertilizers not only increases costs, but also raises questions about food safety.

Another reason for the popularity of plants is that due to the economic recession and the reduction of public construction projects, the global construction industry is eager to seek new development through agricultural investment. Chain catering and supermarket companies hope to build their own vegetable bases to form a stable supply of raw materials. As the manufacturing industry of the electronics industry gradually shifts overseas, a large number of clean factories used to produce precision devices such as chips have been idle. With a little modification, these workshops can be transformed into factories. Therefore, these three industries have become the most active pioneers in investment and construction of factories.

Population expansion and water scarcity are major global problems. The global population is currently 7 billion and may increase to 9.2 billion in the next 40 years. Given that there are still nearly 1 billion hungry people, nearly 58 people need to be added within 40 years. As a percentage of food production capacity; but 80% of the existing arable land has been used, coupled with adverse factors such as abnormal weather, reduced arable land, and the withdrawal of young and growing population from agriculture, the prospects are worrying. In addition, traditional agriculture uses about 87% of the world's freshwater resources, and the substantial increase in productivity per unit area and the establishment of water-saving technologies are topics that urgently need to be studied.

On September 10, 2013, the National Semiconductor Lighting Engineering R&D and Industry Alliance Standardization Committee (CSAS) issued the CSA021-2013 "Plant Growth LED Panel Light Performance Requirements" alliance standard. The standard specifies the terms and definitions, classification and naming, technical requirements, test methods, inspection rules, signs, packaging, transportation and storage of LED flat lights for plant growth.

At present, there are many forms of LED lighting products used for plant growth, such as flat panel lights, double-ended lights, flexible light strips, etc., which will gradually change with the development of technology. CSAS will gradually carry out the standardization of LED lighting for plant growth in accordance with technological development, promote scientific and technological progress, and support industrial development.

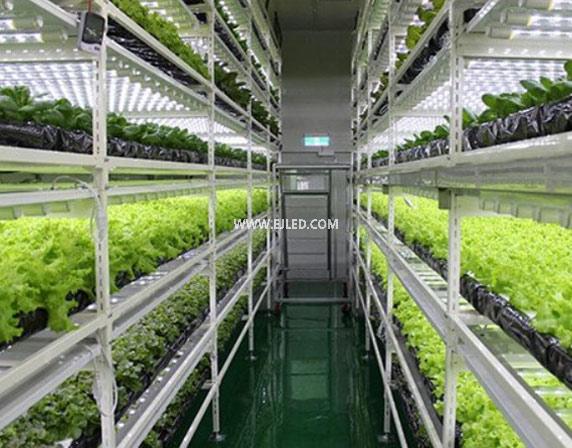

LED grow light market prospects

recently, Tagajo City, Miyagi Prefecture, Japan to the media publicly demonstrated the world's largest LED (light emitting diode) artificial light plant factory. This factory named "Mirai Hata" covers an area of about 2,300 square meters and uses 17,500 LED lighting. It can be produced throughout the year and is expected to harvest about 10,000 lettuce a day. Not long ago, Fujitsu also announced that after about a year of preparation, low-potassium lettuce produced by its own plant factory has begun to be put on the market.

Compared with traditional plant lights, LED plant lights have obvious advantages in energy saving and high efficiency. In 2013, the cost of LED plant lights dropped sharply compared to 2010. Each lumen is equivalent to NT$0.38, which is only 1/5 of NT$1.8 in 2010. This has driven international manufacturers such as Philips, Osram, Mitsubishi, and Panasonic to invest. The innovative application of LED plant factories, Taiwan, which has the advantages of both LED and agricultural industry, certainly does not want to miss out on business opportunities, adding technological innovations to agriculture, allowing enterprises to add value to 100 million yuan.

Japan is the fastest growing country for plant factories. In 2009, the government of this country took the lead in proposing a subsidy policy for plant factories, which triggered the market demand for LED lighting in this field. According to statistics, the demand for LED flat panel lighting in Japanese plant factories in 2009 was 1,000 units, and in 2011, the demand for LED flat panel lighting increased sharply to 8,850 units due to the 311 earthquake. Although it dropped to 2500 units last year, PIDA believes that the demand in the Japanese market will increase year by year. It is expected to reach 3,200 units this year, 9,000 units in 2015, and 18,000 units in 2020.

Taiwan has also begun to smell the business opportunities of plant factories, and many LED companies have begun to enter the market in this field. In addition to Epistar and Everlight, there are Huahao, Canyuan, Guangding, Hongqi, Guanghong, New Century, Northeast and so on. Beginning last year, the Economic Development Bureau also wanted to support plant factories through channels to promote the revitalization of agriculture in Taiwan.

However, Taiwan is small and densely populated, with limited development space. On the contrary, the mainland China market, which is vast and rich in resources, is the goal of all businesses. The Chinese government recently introduced the "Twelfth Five-Year Plan" 863 plan. Although the total funding is only about 46.11 million yuan (about 217 million yuan in Xintai), the plan for the first time lists "smart plant factory production technology research" as a research project. In the 7 projects including the application of LED energy-saving light sources in plant factories, it is clear that the business opportunities for the application of LED lighting in plant factories in China have just emerged.

In my country, after the implementation of the Chinese central government, the market is optimistic that local governments will be more active to keep up. If you see the Chinese government’s previous large-scale subsidy to the LED industry, the next business will be led by plant factories. The opportunities in the field will also bring you the next niche market development opportunity for Taiwan’s LED factories.

In the past, the cost of LED lighting remained high, and plant factories often used fluorescent tubes or high-pressure sodium lamps. With the decline in the price of LEDs and the advancement of technology, new developments have emerged in the application of LEDs in plant factories. At present, there are not many domestic manufacturers engaged in LED plant lights, and most of them are concentrated in Shenzhen. At present, the sales market of LED plant lights is still concentrated in countries and regions with fewer agricultural personnel, such as Japan, South Korea, Central America, Europe and so on. With the extensive development of the modern agricultural industry, LED plant growth lights undoubtedly give these companies a chance to rebirth. However, despite the bright prospects of plant growth lamps, the development of plant factories still faces some "bottleneck". For example, if the initial investment is too large, an artificial light plant factory that produces 1,000 lettuce a day generally requires a relatively high initial investment. Even if the government subsidizes 30%, it often takes 2 years to achieve profitability. In addition, the planting technology in the age of factory agriculture is not yet mature, and related quality control and logistics sales models are also being explored.

Leave a comment